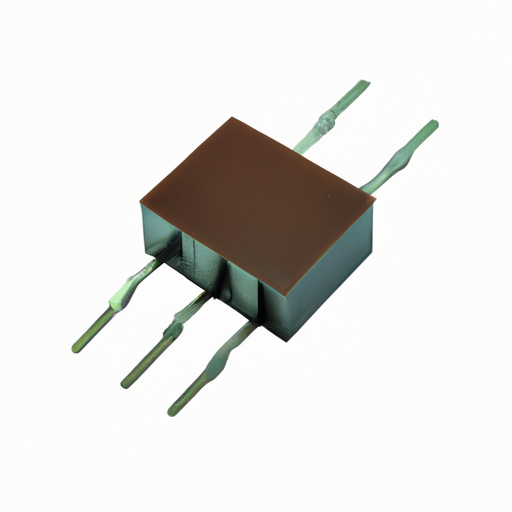

CFR-50JB-52-1R6 Isolation Transformers and Autotransformers: Core Functional Technologies and Application Development Cases

Isolation transformers and autotransformers are essential components in modern electrical systems, providing critical functions in power distribution, voltage regulation, and safety. The CFR-50JB-52-1R6 model serves as a prime example of these technologies, showcasing advancements that enhance performance and reliability. Below, we delve into the core functional technologies, applications, and notable development cases for both types of transformers.

Core Functional Technologies

Isolation Transformers

1. **Electromagnetic Induction**: Isolation transformers operate on the principle of electromagnetic induction, where the primary and secondary windings are magnetically coupled but electrically isolated. This design prevents direct electrical connection, enhancing safety.

2. Voltage Regulation: These transformers can step up or step down voltage levels, providing stable output for sensitive electronic devices. This capability is crucial in environments where voltage fluctuations can lead to equipment failure.

3. Safety Enhancements: By isolating the load from the power source, isolation transformers significantly reduce the risk of electric shock. They also protect sensitive equipment from voltage surges and transients, making them indispensable in critical applications.

4. Noise Filtering: Isolation transformers are effective in reducing electrical noise and interference, which is particularly important in applications such as audio systems and medical devices where signal integrity is paramount.

Autotransformers

1. **Single Winding Design**: Autotransformers utilize a single winding that serves as both the primary and secondary winding. This design allows for a more compact and efficient transformer, particularly beneficial for applications requiring minor voltage adjustments.

2. Step-Up and Step-Down Capabilities: Autotransformers can efficiently step up or step down voltage levels, making them ideal for applications with small voltage differences. Their design often results in lower costs compared to isolation transformers.

3. Higher Efficiency: Due to their construction, autotransformers typically exhibit lower losses and higher efficiency, making them suitable for applications where energy conservation is critical.

Application Development Cases

1. Industrial Automation

- **Isolation Transformers**: In industrial automation, isolation transformers protect sensitive control circuits from high voltage spikes and electrical noise, ensuring reliable operation of control systems.

- **Autotransformers**: Used in motor control applications, autotransformers adjust voltage levels for varying motor speeds, enhancing energy efficiency and performance.

2. Medical Equipment

- **Isolation Transformers**: Critical in medical devices, isolation transformers ensure patient safety by isolating devices from mains supply. They also minimize noise, which is essential for accurate diagnostics in medical imaging and monitoring equipment.

3. Audio and Video Equipment

- **Isolation Transformers**: Employed in high-fidelity audio systems to eliminate ground loops and reduce hum, ensuring superior sound quality.

- **Autotransformers**: Used in video equipment to adjust signal levels, maintaining quality over long transmission distances.

4. Renewable Energy Systems

- **Isolation Transformers**: In solar energy systems, isolation transformers isolate inverters from the grid, enhancing safety and reliability while preventing potential faults from affecting the grid.

- **Autotransformers**: In wind turbine applications, autotransformers adjust voltage levels for grid compatibility, improving overall system efficiency and performance.

5. Power Distribution

- **Isolation Transformers**: Commonly found in substations, isolation transformers step down high transmission voltages to lower distribution voltages, ensuring safe electricity delivery to consumers.

- **Autotransformers**: Utilized in railway systems to adjust traction power voltage levels, providing efficient energy use and reducing infrastructure costs.

Conclusion

Isolation transformers and autotransformers are integral to a wide range of applications, from industrial automation to renewable energy systems. The CFR-50JB-52-1R6 model exemplifies the advancements in transformer technology, offering enhanced safety, efficiency, and reliability. As technology continues to evolve, future developments in these transformers will likely focus on improving energy efficiency, reducing size, and enhancing performance in increasingly complex electrical systems. The ongoing innovation in transformer technology will play a crucial role in meeting the demands of modern electrical infrastructure and applications.